In today’s technical job market, where retirements, automation, and emerging technology are reshaping the workforce, experience and innovation are interdependent. That balance is especially clear in nondestructive examination (NDE), where new tools enter the field every year, yet the fundamentals still rely on patience, hands-on learning, and strong mentorship.

We sat down with Drew Harris, District Manager of our Philadelphia office at CATSI, Inc., to talk about how the skills landscape is shifting, why advanced NDE is becoming increasingly essential, and what young professionals can do to build long, successful careers in this work.

This Q&A has been edited for clarity and organization while preserving Drew’s direct insights and perspective.

Q&A With Drew Harris

Drew Harris

District Manager, Philadelphia Office

CATSI, Inc.

dharris@catsi.com

Q: How have technical skills changed since you started your career?

Drew:

“When I first got into the industry, things looked very different. People who were just starting out in this field were put with good mentors to learn from and would not dare to try and test out for a certification until they were 100% ready. This was after spending a long time in the field with an experienced inspector/technician, learning and gaining the OJT (on-the-job) training hours that are needed.

I’m trying to bring this outlook back to CATSI when bringing on a new hire. If you can show me the work ethic and the ability to want to learn, I’d rather have them taught from the ground up by good, experienced inspectors and technicians.”

Q: Which skills used to be essential to the job, and what’s in demand today?

Drew:

“The biggest things that have always mattered are work ethic, ambition, and integrity. You need the willingness to learn, especially from the person mentoring you. What’s really in demand today is advanced NDE. The East Coast is seriously lacking in people with the technical skills to do this type of work. The technology has been around for a long time, but not manypeople are willing to do it—it’s tedious and requires patience.”

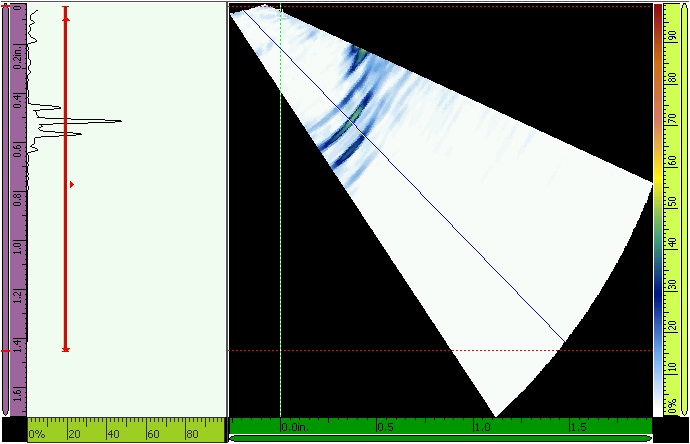

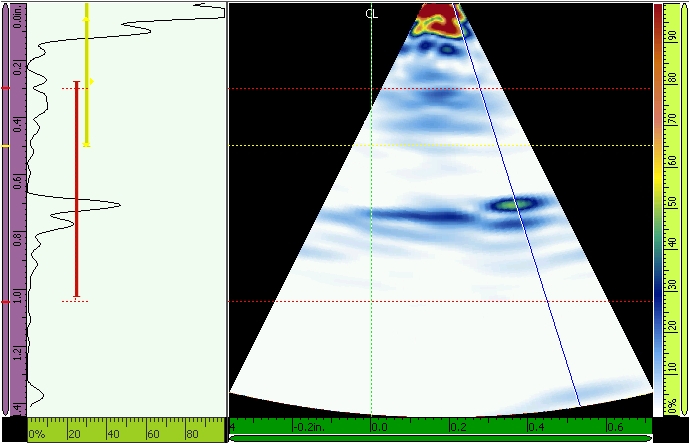

Methods like EMAT, Guided Wave, PEC, Infrared Thermography, and Phased Array Ultrasonics are becoming more central to the industry. Drew sees that shift as an opportunity. “Advanced NDE is where everything is going. It’s a skill that’s in demand and offers a lot of opportunities for growth.”

This insight is why Drew is building a dedicated advanced NDE group at CATSI, supported by strong mentorship and the long-term development of people on his team.

Q: You mentioned the importance of mentorship. What do you think makes a strong mentor?

Drew:

“I think a strong mentor is willing to invest their time and freely share their knowledge. A good mentor explains every tiny detail, like why an indication is called what it’s called, why an inspection is read to a specific code, and why you should take pride in the reporting process of the inspections being turned over to the client. The most important thing is to ask questions and encourage those questions in others.”

Drew added that many companies fall short here. “They rush people through. They don’t ask, ‘Are you ready? Do you need more time?’ Mentorship requires patience.”

Drew sees mentorship as central to the culture at CATSI.

Q: What advice would you give to young professionals entering the field today?

Drew:

“The biggest thing is to look over the person’s shoulder every chance you get. Watch closely and ask a lot of questions. Don’t try to learn everything at once, and don’t rush to achieve every certification. Take your time and build your foundation the right way.”

He emphasized the value of starting from the ground up—something he looks for in new hires. “Michael Barbour, a Level II Infrared Thermographer, is a great example. He came to us from the industrial cleaning side, which is incredibly labor-intensive work. But he showed work ethic and the willingness to learn, and those traits matter more than anything. Those are the people you can mold into the best professionals.”

Q: CATSI is expanding its advanced NDE capabilities. What sparked that growth?

Drew:

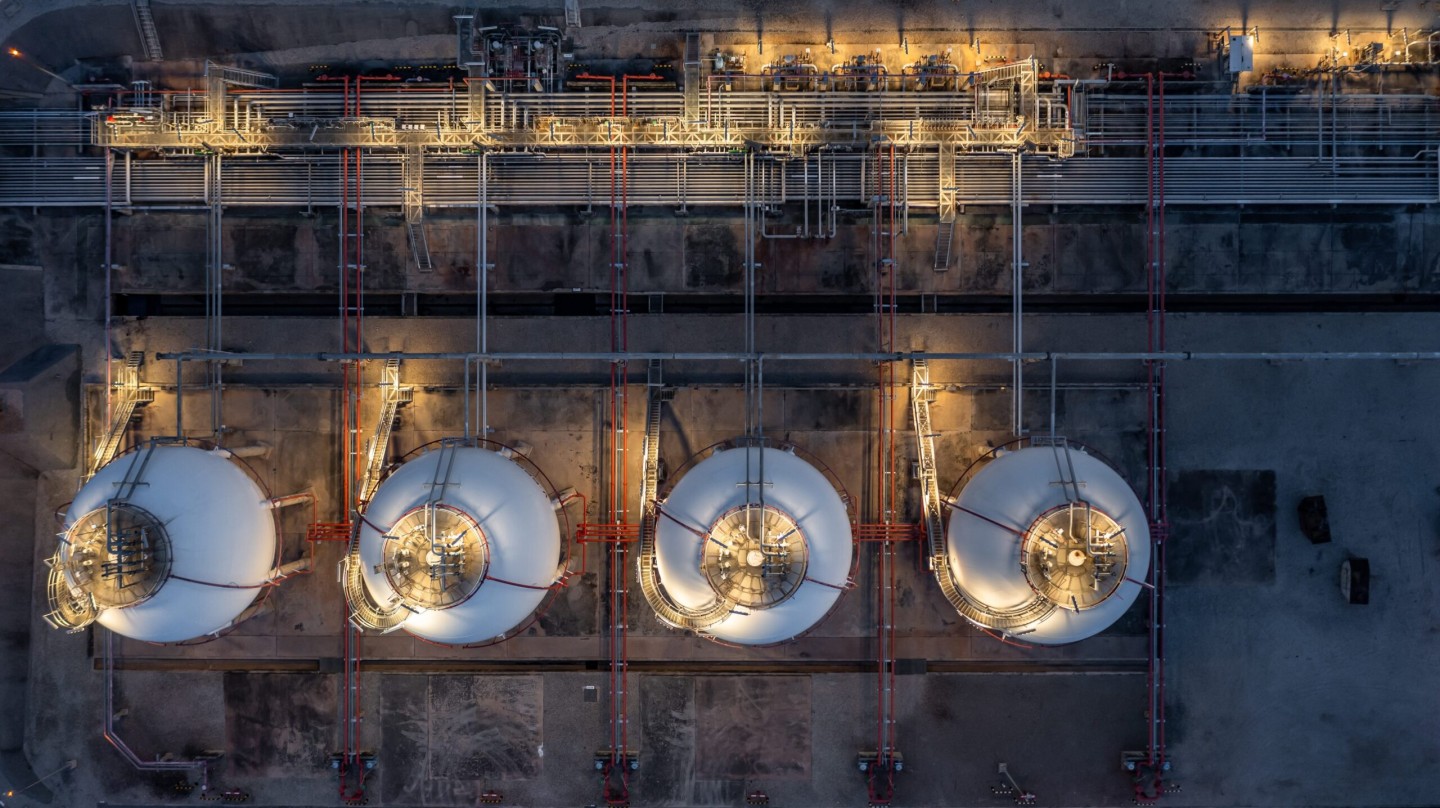

“We use advanced NDE and inspection methods to find problems before they become costly failures. There is a gap in the market, especially here in the Northeast, of companies doing this type of work. It saves clients a lot of time and money and prevents safety hazards. So we are really focused on building our team’s skills in this area.”

A key part of that plan was putting a team in place, led by Ed Haynicz, an Advanced NDE & Infrared Thermography Specialist. “Ed has been doing Advanced NDE for over ten years. He’s the right person to help train others. He asks the right questions, and he cares about getting things right.”

Looking Ahead: Where Experience Meets Innovation

Drew sees the industry continuing to evolve with advancements in technology, more automation, and a wave of retirements that will place enormous value on skilled, well-trained inspectors.

“NDE changes constantly. There’s always something new. That’s why it’s so important for younger guys to learn from someone experienced who can show them how to use the tools the right way.”

For Drew, the future of the field hinges on finding the right talent to be mentored and invested in. That’s how CATSI builds stronger inspectors, stronger teams, and a stronger advanced NDE program—one new professional at a time.